-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

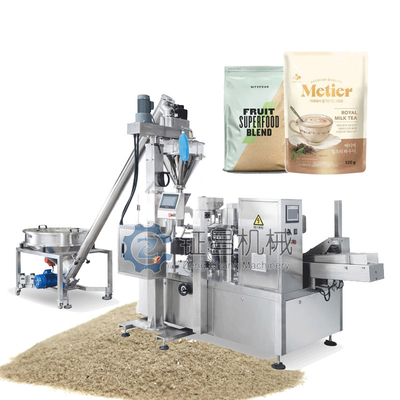

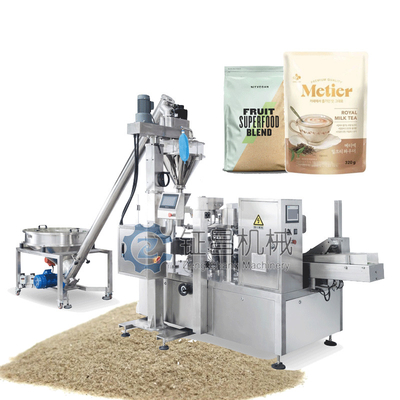

Automatic Bag Feeding Powder Packing Machine Multi Station Solid Beverage

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-X8200 |

| Minimum Order Quantity | 1set |

| Price | $18,000~$29,900 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1set/15day |

| Type | Multi-Function Packaging Machine | Application | Food,Chemical,Medical,Beverage,Commodity |

|---|---|---|---|

| Voltage | 220V/380V | Automatic Grade | Automatic |

| Packaging Material | Plastic | Warranty | 1 Year |

| Highlight | Multipurpose Powder Packing Machine,220V Powder Packing Machine,380V Beverage Packaging Machine |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Automatic Bag Feeding Multi-Station Solid Beverage Packaging Machine Solid Beverage Milk Tea Juice Coffee Packaging Equipment

Multi-station bag feeding machine Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm | 300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

(We can provide you with exclusive customized services according to your needs!)

The solid beverage packaging machine can not only be used to pack powder, but also can be used to pack common powder materials on the market. Solid beverages are a popular powder beverage, such as milk tea powder. Just add some boiling water to the milk tea powder to get a cup of milk tea with a strong milky fragrance.

![]()

Solid beverage packaging machines are available in a variety of styles and models. Common solid beverage packaging machines include: bag-feeding multi-station packaging machines, pouches-feeding single-station packaging machines, vertical packing machines, and bag-feeding horizontal packaging machines machine etc.

![]()

Among them, the automatic pouch feeding multi-station packaging machine is an automatic equipment specially used for packaging prefabricated bags with high appearance requirements. It can complete the opening, printing, filling, sealing, etc. Action, suitable for all kinds of granules, liquids, pastes, flakes, powdery materials, are widely used in food, medicine, beverages, chemicals, agriculture, hardware, toys and other industries.

![]()

Features and Performance:

1. Equipped with a variety of automatic diagnosis and automatic alarm safety protection functions to maximize personal safety and reduce material loss.

2. It can be equipped with a remote diagnosis system, which can troubleshoot the machine in the shortest time.

3. It can be equipped with an automatic lubrication system to prolong the life of the machine and reduce labor costs.

4. It can be equipped with a one-key clip adjustment system to quickly adjust the machine according to the width of the packaging bag.

5. The manufacturing process of the whole machine is strict, and the parts are all made of top international brands.

6. In accordance with international safety and hygiene standards, each machine has passed many safety, environmental protection, physical properties and functional tests.

7. Beautiful appearance, simple operation, stable performance and low failure rate.

![]()