-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

Double Channel Feeding Machine Cans Tinplate Plastic Can Food Filling Machine

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-G37 |

| Minimum Order Quantity | 1set |

| Price | Negotiation |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1/sets/15day |

| Type | Filling Machine | Product Name | Automatic Double Channel Feeding Machine |

|---|---|---|---|

| Material | Stainless Steel | Function | Food,beverage,medical,chemical |

| Filling Speed | 50-80 Cans/min | ||

| Highlight | 0.5MPA Food Filling Machine,0.8MPA Food Filling Machine,Automatic Tin Can Filling Machine |

||

| Machine type | |

|---|---|

| Can sealing machine | |

| Vacuum Sealer | |

| Capping machine | |

| Dust cover capping machine | |

| Granule filling machine | |

| Powder canning machine | |

| Liquid filling machine | |

| Premade Bag Packaging Machine | |

| Vertical bag making and packaging machine | |

| Pre-made bag vacuum packaging machine | |

| Pillow packing machine |

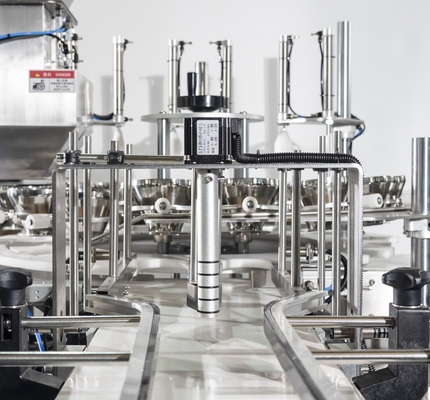

Automatic Double Channel Feeding Machine Cans Tinplate Plastic Can Food Filling Machine

Main Parameters

| Name: | Automatic double channel feeding machine |

| Material: | Stainless steel |

| Air source air pressure: | 0.4~0.8MPA flow rate 0.15 cubic meters per minute |

| Filling speed: | 50-80 cans/min |

| Applicable tank height: | 55-200MM |

| Applicable tank diameter: | 50-130MM |

| Working power supply: | AC220V 50/60HZ (frequency conversion version) |

| Total power: | 1.5KW |

| Weight: | 300KG |

| Dimensions: | 2370*1970*1700MM |

Features:

1. The bottle-feeding shunt device developed by the independent patent adopts the stepper motor to accurately shunt the jar;

2. The rotary table type double station filling simultaneously, the filling speed is 50-80 cans/min;

3. Reserve up to 6-station material insertion/pressing mechanism, and different material insertion and material pressing devices can be installed for special materials to better avoid jamming;

4. Program optimization, select a more suitable blanking mode according to the material properties;

5. The uniquely designed cup vibration mechanism for fragile materials that are not suitable for inserting, the vibration amplitude can be adjusted, and the materials can be quickly charged.

Empty membrane, which helps the material to enter the tank along the intestines;

6. Double gate blanking method saves blanking time and increases efficiency;

7. The parts are precisely processed, and the key parts of the mature production technology are uniquely designed, with high strength, small gaps and no appearance.

burst point;

8. PLC microcomputer control and missing screen man-machine interface, it is very simple and clear to use;

9. Suitable for all kinds of weights, it is an ideal packaging equipment for all kinds of dried fruits, snacks and other industries;

10. The electrical and pneumatic components of the whole machine are made of well-known manufacturers at home and abroad, and the quality is reliable and stable.

![]()

Machine structure:

1. Filling structure: It can be adjusted according to the height of the tank to ensure the filling accuracy and avoid material spillage;

2. Diversion device: precise diversion by stepping motor, so that the bottle is divided into two channels in an orderly manner;

3. Insertion mechanism: for bad materials, add a material insertion station;

4. Vibration mechanism: The vibration mechanism transmits the vibration to the hopper through the tank body, so that the material in the hopper can quickly enter the tank, and at the same time, the material entering the tank can quickly fill the gap, which helps more materials enter the tank smoothly;

5. Double-channel material receiving mechanism: The double-opening type material storage method makes the material unloading and material receiving can be paralleled, reducing the waiting time and improving the efficiency.