-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

M Pouch Horizontal Packaging Machine Enzyme Sauce Capsules 220V/380V

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-S210 |

| Minimum Order Quantity | 1set |

| Price | $16,800.00 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1/sets/15day |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Horizontal Granule Packing Machine | Voltage | 220V/380V |

|---|---|---|---|

| Automatic Grade | Automatic | Condition | New |

| Application | Food,Chemical,Medical,Commodity,Machinery & Hardware | Packaging Type | Bags,Pouch,pouches |

| Highlight | Automatic Sauce Pouch Packing Machine,220V Sauce Pouch Packing Machine,380V Horizontal Sachet Machine |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

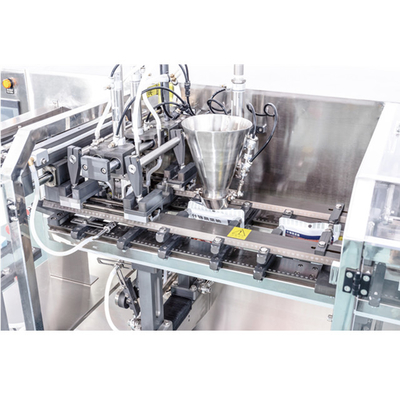

M pouch horizontal packaging machine enzyme sauce capsules

Machine Specification:

| Packing speed | 15-35bags/min |

| Total power | 2.5KW |

| Packing size |

80-160mm/130-320mm (W*L) (M bag adjustable range is 50mm) (packing bag width is slightly different according to prefabricated bags) |

| Power supply | 380V |

| Machine weight | 600KG |

| Packaging capacity | 20g-1000g (depending on specific materials) |

| Packing bag type | M-type bag, M-type stand-up bag and other prefabricated bags |

(We can provide you with exclusive customized services according to your needs!)

![]()

Main features of ZC-S210 M-bag packaging machine:

1. The metering and packaging system includes a horizontal bag feeding and packaging machine and an electronic weighing and unloading system, and the electronic weighing working platform is combined with a Z-type material elevator;

2. It is convenient and simple to put the bag in the bag slot, and it is equipped with an automatic bag pressing device;

3. Equipped with imported pressure sensing device to achieve the effect of no cutting and no sealing, saving packaging bags;

4. Using color touch screen, simple operation, multi-functional design;

5. The machine adopts the appearance of stainless 304L, and the carbon steel frame part and some accessories are processed with acid-resistant and salt-resistant anti-corrosion treatment layer.

6. Material selection requirements: Most of the parts are produced by moulding, and the main materials are 304 stainless and alumina.

7. Various coding, coding, exhaust and punching systems can be selected;

![]()

Scope of application:

Native Packaging Type:

1. Solids: candy, peanuts, green beans, pistachios, puffed food, etc.

2. Granules: beans, crystalline monosodium glutamate, crystalline salt, granular medicines, capsules, seeds, chemical seasonings, chicken essence, melon seeds, pesticides, fertilizers, feed, etc.

![]()

Several precautions for the maintenance of horizontal packaging machines.

1.The horizontal machine should be placed in a ventilated and dry place, and the room temperature is generally maintained at about 25 °C.

2. Apply lubricating oil regularly, mainly on gears, bearings and gearboxes.

3. Regular dust removal to keep the whole machine clean. When not in use, it is recommended to unplug the power supply and cover it with a cloth.

4. The seal should be cleaned regularly to ensure the quality of the seal.

5. The worn parts should be replaced in time to prolong the life of the whole machine.