-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

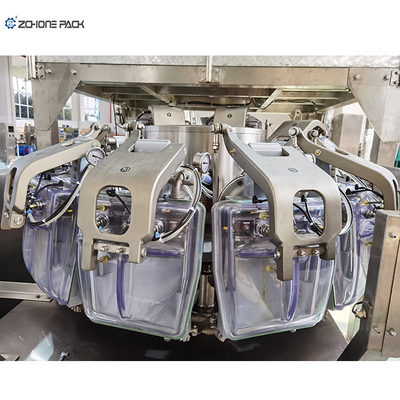

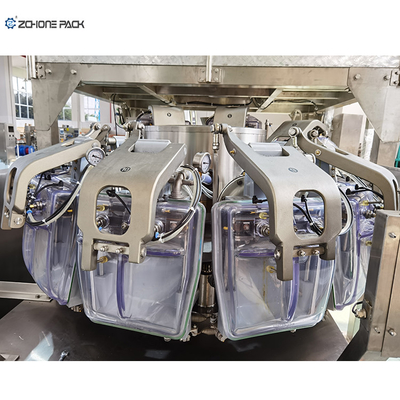

Automatic Vacuum Machine For Packing Bag Vacuum Preservation

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-ZK120 |

| Minimum Order Quantity | 1set |

| Price | $39,900~$68,900 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1/sets/15day |

| Type | Vacuum Packaging Machine | Product Name | Premade Pouch Vacuum Packaging Machine |

|---|---|---|---|

| Voltage | 220V 380V 50/60HZ | Warranty | 1 Year |

| Production Capacity | 20bag/min, 40bag/min, 50bag/min, 30bag/min | Packing Material | Plastic Pouch |

| Highlight | Premade Pouch Vacuum Machine For Packing,Practical Vacuum Machine For Packing,10kw Vacuum Machine For Food Packaging |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Automatic Vacuum Packaging Machine Packaging Bag Vacuum Preservation and Anti-corrosion

Machine Specification:

| Item | ZK120 | ZK160 | ZK200 |

| Packing Speed | Max 60 bags / min | ||

| Bag size | L80-180mm | L80-240mm | L150-300mm |

| W50-120mm | W80-160mm | W120-200mm | |

| Bag Type | Alumiem foil bag, Four-side sealed bag, Paper bag, Laminated bag, etc. | ||

| Weighing Range | 10g~200g | 15~500g | 20g~1kg |

| Measurement Accuracy | ≤±0.5 ~ 1.0%,depend on the measurement equipment and materials | ||

| Maximem bag width | 120mm | 160mm | 200mm |

| Gas consumption | 0.8Mpa 0.3m³/min | ||

| Total power/ voltage | 10kw 380v 50/60hz | 10kw 380v 50/60hz | 10kw 380v 50/60hz |

| Air compressor | Not less than 1 CBM | ||

| Dimension |

L2100*W1400 *H1700mm |

L2500*W1550 *H1700mm |

L2600*W1900* H1700mm |

| Machine Weight | 2000kg | 2200kg | 3000kg |

(We can provide you with exclusive customized services according to your needs!)

Seafood is rich in nutritional value and has become one of the indispensable delicacies on the table. In order to maximize freshness and maintain the taste of aquatic products, many aquatic products are quick-frozen products and then vacuum-packed. Aquatic product manufacturers need to consider comprehensively when choosing packaging equipment, there should be no air leakage, and the packaging speed should be fast. The position of the packaging machine in contact with the material should be made of environmentally friendly materials and will not affect the product. It is best to use fully automatic packaging equipment to reduce the investment in manpower.

![]()

Depending on the packing materials, for the packaging of seafood and other aquatic products, packing machines such as automatic multi-station packaging machines, vertical packaging machines, Mini Doypack Packaging machines, horizontal packaging machines, and vacuum packaging machines can be selected for packaging. For products such as seafood, which have higher requirements for freshness, it is more suitable to use a bag-type vacuum packaging machine for packaging.

![]()

Our vacuum packing machine adopts closed electric scribing ring combined with the conductive heating principle of PLC controlled solid state relay to control vacuum sealing; the advantage is that the heating time is sufficient, the heating time can be adjusted, the number of heating stations can be adjusted, and the heating time is sufficient, avoiding the traditional The copper ring carbon brush method causes false sealing due to carbon deposition, or when the running speed is fast, the sealing is leaked due to insufficient heating time, and the sealing is not strong.

![]()

Features and Functions

1. Prefabricated bags suitable for different requirements;

2. Fully automatic metering, filling and sealing;

4. Made of high-quality stainless steel;

5. Computer PLC control, Chinese display touch screen;

6. Automatically print the production date (optional for coding machine);

7. When the bag fails to be opened, it is not filled or heat-sealed to avoid wasting the bag;

8. Automatic alarm for bag warehouse without bag;

9. When the bag is filled with no material, the heat-sealing station will not work to avoid wasting the bag;

![]()

Aquatic food packaging machine can pack: frozen shrimp, oysters, scallops, squid, fish, sea cucumber, oysters, dried squid, dried small fish, scallops, dried shrimp, shrimp, kelp, wakame, jellyfish head, asparagus, antlers Vegetables and other seafood meat products and seafood vegetarian food.