-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

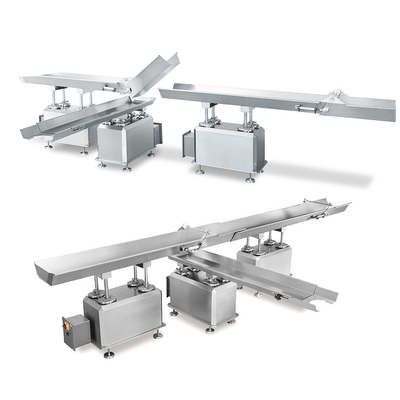

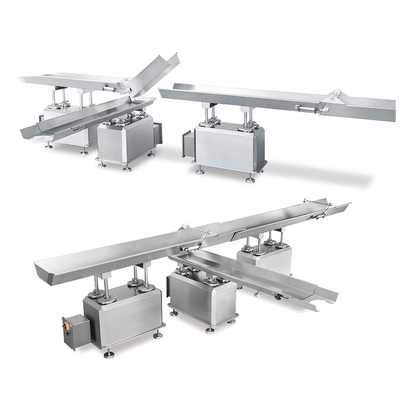

Conveyor Equipment Automatic Packaging Line Rewind Conveyor Food

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-QT1 |

| Minimum Order Quantity | 1set |

| Price | $3,800~$6,800 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1/sets/15day |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Conveyor Equipment | Item | Rewind Conveyor |

|---|---|---|---|

| Transmission Capacity | 10tons/hour | Through Size | 4000*500mm(Customizing) |

| Highlight | 0.25W Automatic Packaging Line,60Hz Automatic Packaging Line,380V Automatic Packing Line |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Conveyor Equipment Automatic Packaging Line Rewind Conveyor Food

Equipment Specification

| Item | Rewind Conveyor |

| transmission Capacity | 10tons/hour |

| Through Size | 4000*500mm(Customizing) |

| Power | 0.25W |

| Voltage | 380V 60Hz |

| Weight | 120Kg |

(We can provide you with exclusive customized services according to your needs!)

With the development of science and technology, the packaging industry has changed from traditional manual packaging to fully automated packaging production lines. Fully automated packaging production line has the advantages of high efficiency and low cost. Its entire working process is controlled by program automation, and the entire operation link can be set and adjusted on the control panel. Before mass production, it is only necessary to set the parameters required for each link on the control panel, and then start with the main switch, the entire equipment can be automatically produced according to the set program. Such a streamlined production can be easily realized on one equipment.

![]()

At present, there are many kinds of conveying equipment on the automatic packaging production line, such as Z-type elevator, screw feeder, bucket elevator, rewind conveyor, etc. For the transportation of some fragile products or food, rewind conveyor are mainly used for transportation. It can provide a clean, gentle product delivery environment, and it can deliver products such as salads, pastries, cookies, candy, etc. quickly and reliably. It solves the problems that occurred in the previous conveying process, such as material loss and adhesion problems.

It is not only very stable during conveying, but also easy to clean and takes up little space, and most importantly, it has a wide range of applications and can also be customized according to the actual space.

![]()

The rewind conveyor has a compact structure and smooth conveying. It also has many characteristics:

1. It can easily and simply replace the conveying trough;

2. It flexibly designs various special conveying troughs;

3. It adopts the design of the end interface of the conveying tray and the design of the middle connection of the conveying trough;

4. It complies with food hygiene and safety standards;

5. It minimizes product breakage;

6. It maximizes the protection of powder products during transportation;

7. Its running process is very quiet;

8. It can be opened or stopped at any time, and can meet the conveying requirements of automatic packaging machines;

9. Its conveying tray is easy to clean.