-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

Activated Carbon Powder Packaging Machine Premade Bag Self-supporting BagOpen ZipperAutomatic Dust Removal

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-X8300 |

| Minimum Order Quantity | 1set |

| Price | $18,000~$29,900 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1set/15day |

| Type | Multifunctional Packaging Machine | Product Name | Coffee Powder Packaging Machine |

|---|---|---|---|

| Application | Food,Medical,Chemical,Commodity,Machinery & Hardware | Weighing Range | 10g-3kg |

| Certification | CE/ISO9001 | Warranty | 1 Year |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Activated Carbon Powder Packaging Machine Premade Bag Self-supporting BagOpen ZipperAutomatic Dust Removal

In view of the problem that activated carbon powder is prone to dust generation during bag packaging, configuring a professional dust removal device is a key measure to ensure a clean production environment and safe operation.

1. Dust removal device configuration plan

Negative pressure dust collection system

Working principle: Install a dust hood at the dust generation point such as the feeding port and filling port of the packaging machine, and generate negative pressure through the centrifugal fan to suck the floating activated carbon dust into the dust collection pipe.

Key components:

Explosion-proof fan (activated carbon dust is flammable and requires ATEX certification)

High-efficiency filter (such as HEPA or PTFE coated filter cartridge, filtration accuracy ≥ 0.3μm)

Dust collection bucket (with anti-static design, capacity matched according to production)

Pulse backwash dust collector

Applicable scenario: high dust environment for continuous production.

Advantages: automatic cleaning of filter cartridges to avoid blockage and long maintenance cycle.

Recommended parameters: processing air volume ≥ 2000m³/h, filtration area ≥ 30㎡ (adjusted according to equipment specifications).

Wet dust removal system

Applicable scenario: environment with extremely high explosion-proof requirements.

Principle: Capture dust through water mist to reduce the risk of explosion.

Note: Sewage needs to be cleaned regularly to avoid activated carbon deposition.

Partially enclosed design

Install transparent dust curtains or enclosed cabins at the filling station of the packaging machine to reduce dust escape.

2. Selection considerations

Explosion-proof requirements

Activated carbon dust is explosive (lower explosion limit 20-50g/m³), and the dust removal equipment must comply with ATEX/IECEx standards and be equipped with explosion-proof discs or explosion-proof valves.

Material compatibility

Parts in contact with activated carbon (such as filter materials and pipes) should be made of anti-static and wear-resistant materials (such as stainless steel 316L).

Air volume matching

The wind speed at the dust suction point is recommended to be ≥1.5m/s, and the total air volume is calculated according to the number of packaging machine stations (for example: 500m³/h for a single point and 2000m³/h for 4 points).

Maintenance convenience

Select a quick-detachable filter cartridge design, and the dust collection bucket is equipped with a material level sensor to remind timely cleaning.

3. Operational recommendations

Regular inspection: Clean the filter cartridge weekly and test the effectiveness of the explosion-proof device.

Employee protection: Operators should wear dust masks (such as 3M 8210) and goggles.

Environmental monitoring: Install a dust concentration alarm (such as MSA Altair 4X).

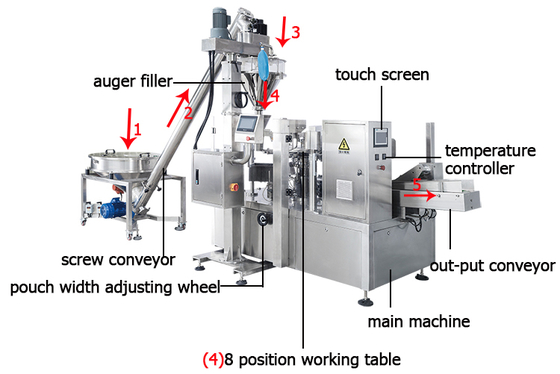

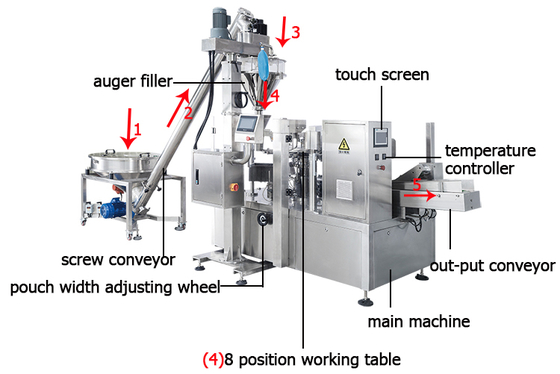

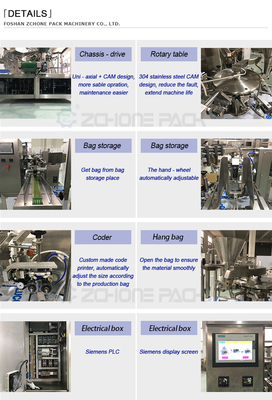

Eight-station packing machine Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm | 300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

(We can provide you with exclusive customized services according to your needs!)

![]()

![]()

![]()

![]()