-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

Automatic Ice Cubes Filling Weighing Vertical Packaging Machine Beverage and Food with Roll Film Bags - Easy to Operate

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-200 |

| Minimum Order Quantity | 1set |

| Price | $9,800~$28,900 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1/sets/15day |

| Type | Multi-Function Packaging Machine | Product Name | Mini Doypack Packing Machine |

|---|---|---|---|

| Warranty | 1 Year | After Warranty Service1 | Video Technical Support |

| After Warranty Service2 | Online Support | After Warranty Service3 | Spare Parts |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Automatic Solid Granule Ice Cubes Filling & Weighing Vertical Packaging Machine for Beverage and Food with Roll Film Bags - Easy to Operate

This is an automated machine specifically designed for packaging bagged ice cubes (such as edible ice, industrial ice, and cooling ice packs). It belongs to a specialized subcategory of vertical packaging machines (also known as bag-making-filling-sealing machines).

I. Core Working Principle

The basic workflow of a vertical packaging machine is "bag making first, then filling." For ice cube packaging, the specific steps are as follows:

1. Bag Making: The packaging film (usually a composite plastic film) on the roll is pulled downwards, rolled into a cylindrical shape by a forming device, and then heat-sealed longitudinally to form a continuous cylindrical film.

2. Metering and Filling: This is the most crucial and challenging part. The filling method for ice cubes differs from other granules/powders.

3. Multi-head Combination Weigher: The most accurate and advanced method. Ice cubes are fed into multiple metering hoppers via a vibratory feeder or other conveying method. A computer calculates and quickly reaches the target weight (e.g., 5 kg/bag). Then, multiple hopper doors open simultaneously, "pouring" the ice cubes into the pre-formed membrane cylinder.

4. Volumetric Filling: The filling volume is controlled by adjusting the size of the feed cup. Accuracy is relatively low, and it is greatly affected by the size and shape of the ice cubes.

5. Screw Metering: Suitable for small particles or crushed ice; less suitable for standard ice cubes.

6. Gross Weight Filling: Dynamic weighing is performed during filling, stopping once the target weight is reached. Slower speed, higher accuracy.

7. Lateral Sealing and Forming: The ice-filled membrane cylinder is simultaneously sealed and cut laterally at both ends by a lateral sealing mechanism (usually a heated heat-sealing knife). This seals the top of the current bag and the bottom of the next bag, completing an independent, sealed ice bag.

8. Finished Product Output: Packaged ice bags are conveyed out via a conveyor belt and can be connected to an automatic case packer or palletizing equipment.

II. Main Features and Special Requirements of the Equipment

1. Low Temperature Resistance and Waterproofing:

Key components of the equipment (such as hoppers, conveyor channels, weighing hoppers, etc., that come into contact with ice) need to be made of stainless steel (e.g., 304/316) and treated with rust prevention.

The electrical system and sensors need to have good waterproof and condensation-proof design due to the humid and low-temperature working environment.

2. Wear Resistance and Impact Resistance:

Ice is hard and has a large impact force when falling. Parts of the equipment that come into contact with ice need to be thickened or treated with wear resistance.

3. Efficient Cooling and Conveying System:

Typically connected to upstream ice makers (flake ice machines, cube ice machines, etc.) and ice storage/ice silos.

A bridging/ice-uniforming system (such as a hopper with a bridging blade, a vibrator) is required to prevent ice from arching in the hopper and ensure smooth feeding.

4. Packaging Speed:

Speed depends on the weight of each bag and the level of automation. Small bags (e.g., 500g-1kg) are packaged faster, reaching 20-40 bags/minute; large bags (5kg-20kg) are packaged slower, typically 5-15 bags/minute.

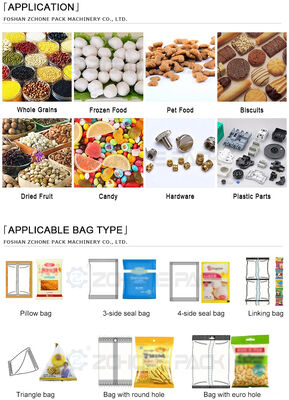

5. Packaging Bag Types:

Mainly producing back-seal bags (three-side seal) or four-side seal bags.

A perforator can be added to create ice packs that are easy to hang or carry.

III. Main Application Areas

1. Edible Ice: Bagged edible ice for retail use in restaurants, bars, hotels, and supermarkets.

2. Industrial/Commercial Ice: Large packages of ice for seafood transportation, food processing, concrete cooling, chemical industries, etc.

3. Medical Ice/Cold Compress Ice Packs: Cold compress ice packs used in hospitals, clinics, and sports rehabilitation.

4. Emergency Cooling Ice: Used for outdoor activities, sporting events, agricultural cooling, etc.

Machine Specification:

| Model | ZC--VP32 | ZC-VP42 | ZC-VP52 | ZC-VP62 |

| Packing Speed | 10-50 bags/min | 10-50 bags/min | 10-50 bags/min | 5~50 bags/min |

| Bag Size | (L) 50- 190mm (W) 50-150mm | (L) 80-320mm (W) 70- 200 mm | (L) 80-320mm (W) 70- 200 mm | (L)120-400mm (W)110- 300mm |

| Bag Making Form | Pillow type back seal bag (roll film for packaging material, automatic bag making by machine is upper sealing, lower sealing and back sealing.) | Pillow bag (optional: stand-up bag, prong bag, punch bag)) | ||

| Maximum Packaging Film Width | 320mm | 420mm | 420mm | Max 2500ml |

| Measurement Range | 500ml | 1000ml | 1000ml | 620mm |

| Membrane Thickness | 0.04- 0.12mm | 0.04-0.10mm | 0.04-0.10mm | 0.04-0.14mm |

| Complete Set of Air Consumption | 0.8Mpa 0.5m3/min | 0.8Mpa 0.3m³/分 | 0.8Mpa 0.3m³/分 | 0.8Mpa 0.5m3/min |

| Total Power/Voltage | 2.5KW/220V 50Hz | 2.7KW/220V 50Hz | 2.7KW/220V 50Hz | 4.2KW/220V 50Hz |

| Dimensions | (L)1350* (W)820* (H)1150mm | L1480*W960*H1400mm | L1480*W960*H1400mm | L1964*W1240*H1960mm |

| Switchboard Weight | 380kg | 450kg | 450kg | 450kg |

(We can provide you with exclusive customized services according to your needs!)

![]()

![]()

![]()

![]()