-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

Automatic Packing Machine Accessories Metering Equipment Multi Head Scale Granule

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-M10 |

| Minimum Order Quantity | 1set |

| Price | $4200~$15800 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1/sets/15day |

| Product Name | Multi-head Combination Scale | Function | Suitable For Weighing Particles And Solid Materials |

|---|---|---|---|

| Weighing Range | 10-1000 Grams | Max. Speed | 65 Bags/min |

| Gross Weight | 400 Kg | Packing Dimension | 1620L*1100W*1100H Mm |

| Highlight | 65bags/min Packing Machine Accessories,Multihead Scale Packing Machine Accessories,450kg Multi Head Scale |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Automatic Packing Machine Metering Equipment Multi-head Scale Granule Packing Machine

Equipment Specification:

| Model | ZC-M10 | ZC-M14 |

| Weighing Range | 10-1000 grams | 10-2000 grams |

| Max. Speed | 65 bags/min | 120 bags/min |

| Accuracy | + 0.1-1.5 grams | + 0.1-1.5 grams |

| Weigh Bucket Volume | 1.6 or 2.5L | 1.6 or 2.5L |

| Control Penal | 7" Touch Screen | 7" Touch Screen |

| Power Supply | 220V/50HZ or 60HZ; 10A; 1000W | 220V/50HZ or 60HZ; 12A; 1500W |

| Driving System | Stepper Motor | Stepper Motor |

| Packing Dimension | 1620L*1100W*1100H mm | 1720L*1100W*1100H mm |

| Gross Weight | 400 kg | 450 kg |

(We can provide you with exclusive customized services according to your needs!)

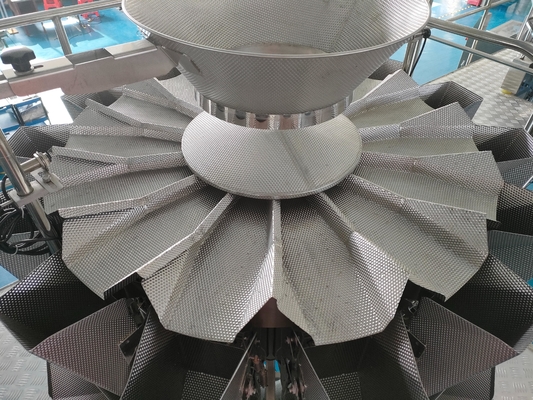

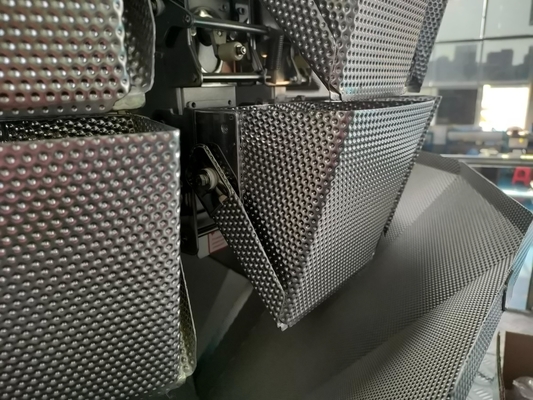

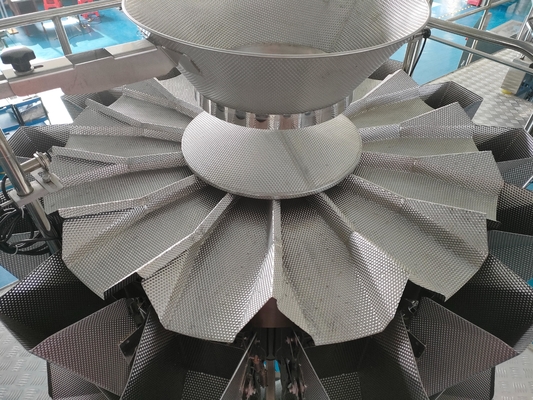

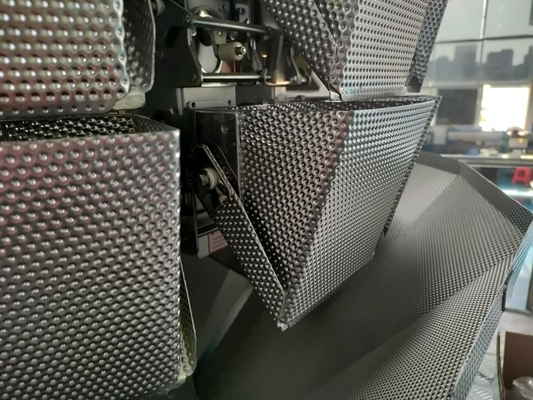

Multi-head combination scale is an automatic weighing equipment for pouch packaging machine. It is mainly used for fully automatic weighing of solids and granules, such as: potato chips, snacks, dried fruits, chocolate, candy, seeds, popcorn, pet food, etc. Compared with the traditional manual weighing, the fully automated weighing system can complete the weighing of the product independently without manual participation, and the weighing weight is more accurate and the weighing speed is faster. It occupies an important position in the entire fully automated packaging production line.

![]()

As a packaging machine measuring equipment, the multi-head scale can be used for various solid packaging models, such as automatic rotary packaging machine, automatic granule vertical packing machine, automatic mini doypack pouch packing machine, and vacuum packing machine etc. It is paired with Z-type elevator, support platform, packaging machine host, and finished product conveyor to form a complete fully automated granule packaging production line. In addition, there are many kinds of packaging machine metering equipment, such as liquid pump, auger filler, paste pump, linear weigher, volumetric cups device etc.

![]()

The working principle of the multi-head scale:

1. The product is vibrated by the main vibrating machine in the cross-cutting hopper, so that the material is evenly distributed on the conical funnel to the line vibrating plate.

2. When the material in the cross-cutting bucket is not or not enough to be detected by the horizontal photoelectric detector, it will send a signal like the main board, and then send a feeding signal to the Z-type elevator through the main board to feed.

3. The wire vibrating plate vibrates, and the product is sent to each feeding hopper by the amplitude and the feeding time of the wire vibrating machine.

4. The driving device, that is, the stepping motor, opens the feeding hopper and sends the product to the weighing hopper. When there is no product in the weighing hopper below or when the product in the weighing hopper is not enough, the product will automatically flow into the weighing hopper.

![]()

Equipment Features:

- IP65 waterproof, use water cleaning directly, save time while cleaning;

- Modular control system, more stability and lower maintenance fees;

- Production records can be checked at anytime or download to PC;

- Load cell or photo sensor checking to satisfy different requirements;

- Preset stagger dump function to stop blockage;

- Design linear feeder pan deeply to stop small granule products leaking out;

- Refer to product features, select automatic or manual adjust feeding amplitude;

- Food contact parts disassembling without tools, which is easier to clean;

- Multi-languages touch screen for various clients, English, French, Spanish, etc;

- PC monitor production status, clear on production progress (Option).