-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

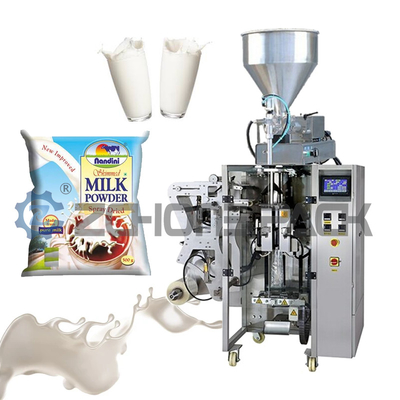

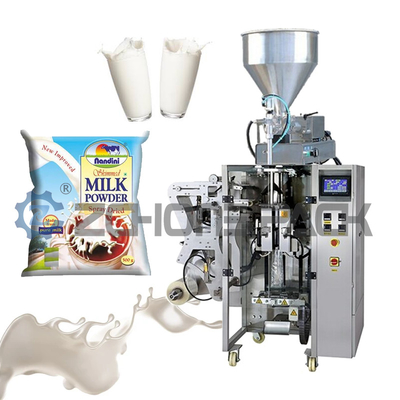

50pcs / Min Milk Packing Machine Bag Liquid Vertical Packaging Equipment

| Type | Liquid Vertical Packing Machine | Warranty | 12 Month |

|---|---|---|---|

| Application | Sauce, Seasoning Oil, Chili Oil, Sesame Oil, Peanut Oil, Salad Oil, Hot Pot Base, Seasoning Sauce, Tomato Sauce, Peanut Sauce, Sesame Sauce, Spicy Sauce, Chili Sauce, Bean Sauce, Hoisin Sauce, Sweet Noodle Sauce, Salad Sauce, Fruit Sauce, Etc. | Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Construction Works , Energy & Mining, Food & Beverage Shops |

| Core Components | Motor, Pressure Vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox | Production Capacity | 50bag/min, 30bag/min, 60bag/min |

| Highlight | 50pcs / Min Milk Packing Machine,Vertical Liquid Milk Packing Machine |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Milk Packing Machine Bag Liquid Vertical Packaging Equipment

Machine Specification:

| Model | ZC--VP32 | ZC-VP42 | ZC-VP52 | ZC-VP62 |

| Packing Speed | 10-50 bags/min | 10-50 包/分钟 | 10-50 包/分钟 | 5~50 bag/min |

| Bag Size | (L) 50-190mm (W) 50-150mm | (L) 80-320mm (W) 70-200 mm | (L) 80-320mm (W) 70-200 mm | (L)120-400mm (W)110-300mm |

| Bag Making Form | Pillow type back seal bag (roll film for packaging material, automatic bag making by machine is upper sealing, lower sealing and back sealing.) | Pillow bag (optional: stand-up bag, prong bag, punch bag)) | ||

| Maximum Packaging Film Width | 320mm | 420mm | 420mm | Max 2500ml |

| Measurement Range | 500ml | 1000ml | 1000ml | 620mm |

| Membrane Thickness | 0.04-0.12mm | 0.04-0.10mm | 0.04-0.10mm | 0.04-0.14mm |

| Complete Set of Air Consumption | 0.8Mpa 0.5m3/min | 0.8Mpa 0.3m³/分 | 0.8Mpa 0.3m³/分 | 0.8Mpa 0.5m3/min |

| Total Power/Voltage | 2.5KW/220V 50Hz | 2.7KW/220V 50Hz | 2.7KW/220V 50Hz | 4.2KW/220V 50Hz |

| Dimensions | (L)1350*(W)820*(H)1150mm | L1480*W960*H1400mm | L1480*W960*H1400mm | L1964*W1240*H1960mm |

| Switchboard Weight | 380kg | 450kg | 450kg | 450kg |

(We can provide you with exclusive customized services according to your needs!)

Milk packaging machines can be roughly divided into bagged liquid packaging machines and bottled liquid packaging machines. A bag milk packing machine is a type of machinery that is used to package milk into bags. This machine is commonly used in the dairy industry to package milk in bags for sale to consumers. The machine is designed to automatically fill and seal the bags with milk.

The bag milk vertical packing machine typically consists of a filling station, a bag-forming station, a sealing station, and a cutting station. The filling station is where the milk is pumped into the bags. The bag-forming station creates the bags from rolls of plastic film. The sealing station seals the bags shut to prevent any leaks, and the cutting station separates the bags from each other.

Bag milk packing machines can vary in size and capacity depending on the needs of the dairy. Some machines are designed to package smaller quantities of milk, while others can package larger volumes. These machines are typically automated, making them efficient and reliable.

Overall, bag milk packing machines play a crucial role in the dairy industry by allowing milk producers to package their products quickly and efficiently, while also ensuring the freshness and quality of the milk.

![]()

![]()