-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

Eight-station rotary liquid packaging machine prefabricated bag 304/316 stainless steel

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-8200 |

| Minimum Order Quantity | 1set |

| Price | $18,000~$24,900 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1/sets/15day |

| Product Name | Spout Packing Machine | Place Of Origin | Foshan China |

|---|---|---|---|

| Application | Beverage, Liquid & Juice | Packaging Material | Plastic |

| Voltage | 220V 380V 50/60HZ | Key Selling Points | Automatic |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Eight-station rotary liquid packaging machine prefabricated bag 304/316 stainless steel

Liquid rotary eight-station bag-feeding packaging machine is an automated packaging equipment dedicated to prefabricated bags (i.e. prefabricated packaging bags), suitable for filling, sealing, coding and other processes of liquids, sauces, pastes and other products. Its core feature is the coordinated operation of rotary multi-stations, combined with the automatic bag-feeding system to achieve a high-efficiency and high-precision packaging process.

1. Equipment Overview

Functional Positioning:

Designed specifically for prefabricated bags, it completes the entire process of automatic bag taking → bag opening → filling liquid → exhaust → sealing → coding → output, and is suitable for viscous liquids (such as sauces, honey, detergents) or low-viscosity liquids (such as beverages, oil and vinegar).

Core advantages:

Prefabricated bag adaptability: It can handle prefabricated bags of various materials (aluminum foil bags, composite film bags, etc.), and the packaging appearance is exquisite.

Leak-proof design: Optimize the sealing process according to the characteristics of the liquid (such as double-channel heat sealing, cooling and shaping).

High integration: The rotary station is compact, space-saving, and has high production capacity (usually 40-80 bags/minute).

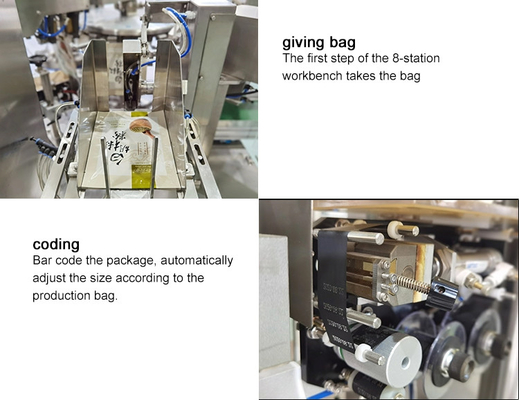

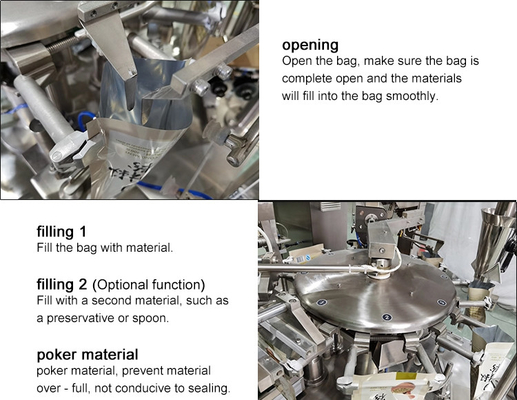

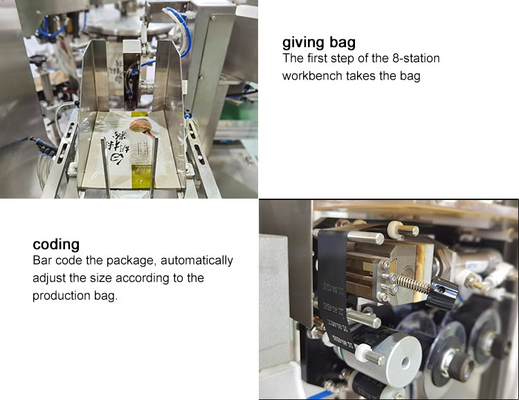

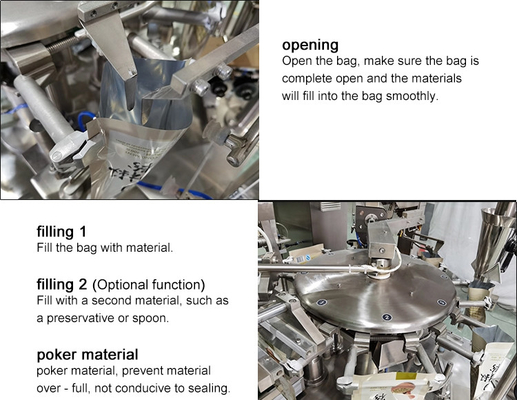

2.Typical eight-station process

(Specific stations can be adjusted according to needs)

Empty bag loading: The robot or suction cup accurately takes the bag from the bag library and transports it to the station.

Bag opening: Air pressure or clamping device opens the bag mouth, which may be assisted by blowing.

Bag shaping: Ensure that the opening is flat for easy filling.

Liquid filling: High-precision pump or gravity filling, optional anti-drip nozzle.

Exhaust finishing: Vibrate or squeeze to expel air from the bag to avoid seal contamination.

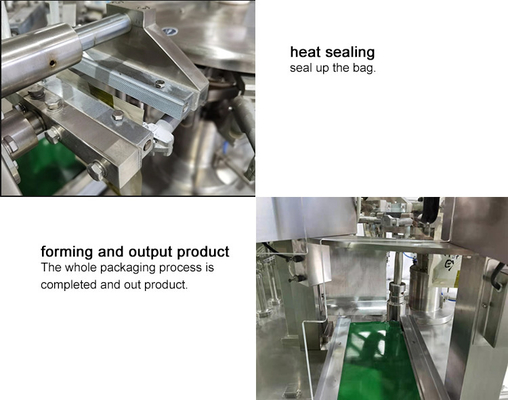

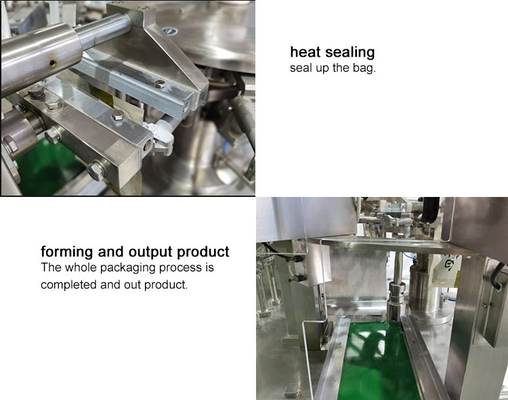

Heat sealing: Double-pass heat sealing (temperature controllable) to ensure sealing.

Cooling and shaping (optional): Cooling plate pressurization to prevent seal deformation.

Finished product output: conveyor belt or robot removes, and defective products are detected and removed simultaneously

3.Application scenarios

Food industry: seasoning sauce, hot pot base, liquid milk, jelly.

Daily chemical industry: hand sanitizer, shampoo, skin care products.

Pharmaceutical industry: Chinese medicine liquid, disinfectant.

Industrial field: adhesives, lubricants.

Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm | 300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

(We can provide you with exclusive packaging machine customization services according to your needs! Of course,If you need, we can also provide you with customized bag service)

![]()

![]()

![]()