-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

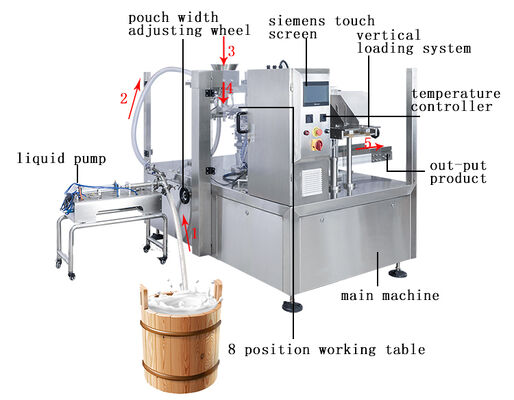

Eight-Station Fully Automatic Liquid Beverage and Food Packaging Equipment with Hydraulic Drive

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-200 |

| Minimum Order Quantity | 1set |

| Price | $18,000~$36,900 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1set/15day |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Multifunctional Packaging Machine | Product Name | Rotary Packaging Machine |

|---|---|---|---|

| Function | FILLING, Labeling, Sealing | Key Selling Points | Automatic |

| Maximum Bag Width | 200mm | Warranty | 1 Year |

| Highlight | hydraulic drive liquid packaging machine,fully automatic beverage packaging equipment,eight-station food packing machine |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Eight-Station Fully Automatic Liquid Beverage and Food Packaging Equipment with Hydraulic Drive

The eight-station liquid packaging machine is a highly efficient and automated rotary liquid filling and sealing device, widely used in the food, beverage, daily chemical, and pharmaceutical industries.

I. Core Working Principle: Rotary Intermittent Motion

The machine's main shaft drives eight station turntables in intermittent rotational motion (usually controlled by a cam divider to ensure precise positioning). Each station completes a specific operation during a stationary period and switches to the next station during a rotating period, repeating the cycle to form continuous production.

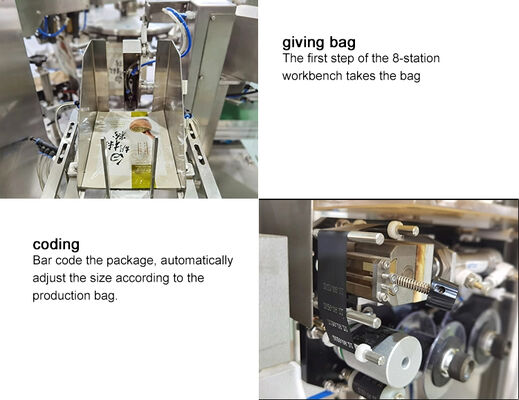

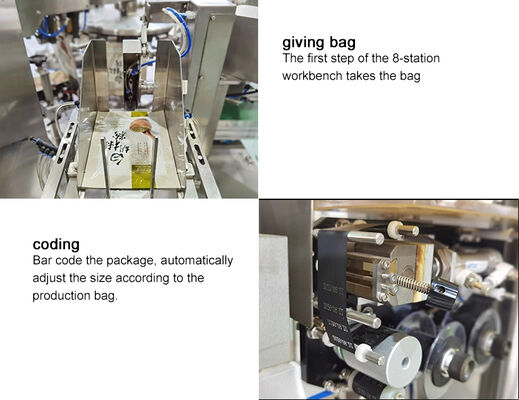

II. Typical Workflow of Eight Stations

This is the core of the machine. Although the sequence may vary slightly between different models, a standard eight-station workflow is as follows:

1. Station One: Empty Container Loading

Empty bottles/cups/bags are placed into the clamps or molds using a bottle unscrambler or manually, and automatically clamped and positioned.

2. Station Two: Positioning and Inspection (Optional)

Inspects whether the container is in place and in normal condition. If any items are missing, subsequent stations (such as filling) can automatically skip them to avoid waste.

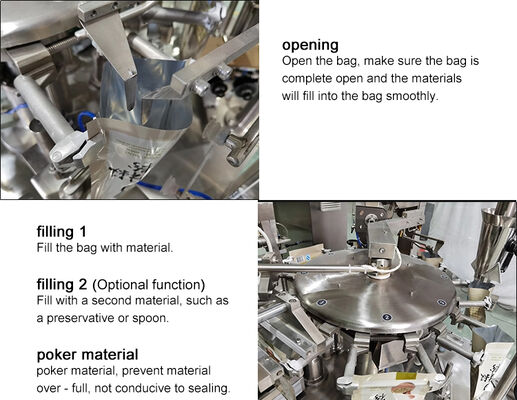

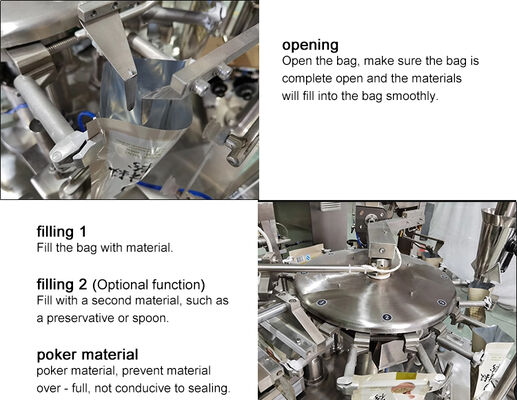

3. Station Three: First Filling (if required)

For liquids requiring mixed or layered filling, the first liquid is quantitatively filled at this station.

4. Station Four: Second Filling / or Main Single Filling Station

In most cases, this is the main filling station. High-precision quantitative filling is performed using **volumetric filling** (e.g., peristaltic pump, plunger pump) or gravity filling. The filling head can be raised and lowered to prevent foaming.

5. Station Five: Post-Filling Inspection (optional)

The filling volume is checked for compliance using weighing or a level sensor.

6. Station Six: Sealing

This is a critical station. The method varies depending on the packaging material:

For flexible bags: heat sealing or ultrasonic sealing.

7. Station Seven: Cooling and Shaping (for heat sealing)

Cooling and shaping the heat-sealed area ensures a firm and aesthetically pleasing seal.

8. Station Eight: Finished Product Unloading

The fixtures automatically open, and the finished product is pushed onto the conveyor belt for the next stage (e.g., boxing, coding, cartoning).

Note: The entire process is fully automated under the control of a PLC (Programmable Logic Controller) and a touchscreen human-machine interface, allowing adjustment of all parameters such as speed, filling volume, and temperature.

III. Main Application Features

1. High Efficiency: Eight stations operate simultaneously, ensuring stable output. Speed varies depending on the product, typically reaching 2000-6000 units or more per hour.

2. High Precision: Employing a high-precision pump or servo control system, filling accuracy can reach ±0.5% - ±1%.

3. High Adaptability: By changing the filling head, fixtures, and molds, it can adapt to containers of different shapes and capacities (e.g., round bottles, square boxes, irregularly shaped cups).

4. Hygiene and Safety:

The main material contact parts are made of 316/304 stainless steel, meeting GMP (Good Manufacturing Practice) requirements.

5. Easy to disassemble and clean (CIP/SIP function optional), with no unsanitary corners.

6. High Stability: Core transmission components (such as dividers, servo motors, and guide rails) are from well-known brands, ensuring stable continuous operation over long periods.

7. Intelligent: Equipped with functions such as production counting, fault alarms, data recording, and formula storage.

IV. Main Application Industries and Products

1. Food and Beverage: Yogurt, jelly, pudding, sauces, juices, milk, hot pot base.

2. Daily Chemicals: Laundry detergent, hand soap, shampoo, lubricating oil.

3. Pharmaceuticals and Chemicals: Disinfectants, eye drops, oral liquids, veterinary drugs, reagents.

Eight-Station Fully Automatic Liquid Beverage and Food Packaging Equipment with Hydraulic Drive

Machine Specification:

| Item | 200 | 300 | 430 |

| Bag Material | Multilayer Composite Premade Bag (e.g.: PET/PE) | ||

| Bag size | 100mm≤L≤200mm | 100mm≤L≤300mm | 100mm≤L≤430mm |

| 70mm≤W≤150mm | 80mm≤W≤300mm | 80mm≤W≤300mm | |

| Bag Type | 3 Side Seal Bag, Stand-up Bag | ||

| Upgradable Bag Type | N/A |

Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device) |

|

| Speed | 0~26bags/min | 0~15bags/min | |

| Sealing Type | Plain weave | Straight grain, pitch is 1mm (Optional reticulate) | |

| Sealing Width | 8mm | 10mm(5--20mm can be customized) | |

| Voltage | 220V, Single-phase, 50/60HZ, 1KW | 220V, Single-phase, 50/60HZ, 1.2KW | |

| Air Pressure | 0.65Mpa | ||

| Air Consumption | 0.2m³/min | 0.3m³/min | |

| Standard machine, no additional function | |||

| Body Dimension | 1080*535*1010mm | 1770*600*1230mm | 1770*600*1360mm |

| Packing Dimension | 1240*670*1320mm | 1860*710*1550mm | 1860*710*1650mm |

| Export non-fumigation wooden case | |||

(We can provide you with exclusive packaging machine customization services according to your needs! Of course,If you need, we can also provide you with customized bag service)

![]()

![]()

![]()

![]()

![]()