-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

Poria Herb Granule Bag Packing Machine Automatic Multifunctional High Speed Packaging Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Automatic Packaging Machine | Product Name | Food Granule Multi-station Packaging Machine |

|---|---|---|---|

| Dimension(L*W*H) | L1900*W1400*H1450 | Weight (KG) | 1300 |

| Voltage | 110V 220V 380V 50hz/60hz | Production Capacity | 20bag/min, 50bag/min, 30bag/min |

| Highlight | Automatic Granule Packing Machine,Multifunctional Granule Packing Machine,High Speed Granule Packing Machine |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Poria Herb Granule Bag Packing Machine Automatic Multifunctional High Speed Packaging Machine

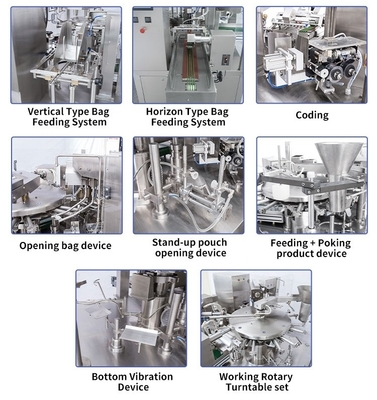

The Poria transparent pouch packaging machine is a machine specially used for packaging Poria or other small granular items. It can automatically put items such as Poria into transparent pouches and seal them.

Here is some relevant information:

Applicable products: The Poria transparent pouch packaging machine is mainly used to package small granular items such as Poria. Poria is a Chinese herbal medicine that is widely used in traditional Chinese medicine and health care products industries.

Packaging form: This packaging machine usually uses transparent plastic film to make pouches. This transparent packaging form can clearly show the appearance and quality of the items in the bag.

Automation control: The Poria transparent pouch packaging machine is usually equipped with an automatic control system, which can realize the automation of the entire packaging process. This includes steps such as bag formation, filling, and sealing.

Sealing technology: Commonly used sealing technologies include heat sealing, ultrasonic sealing, or pressure sealing. These technologies can ensure the sealing of the bag mouth and prevent leakage and oxidation of Poria or other items.

Packing speed and capacity: The specific packaging speed and capacity depend on the machine model and configuration. Different Poria transparent pouch packaging machines can have different packaging speeds and maximum capacities to meet different production needs.

Customizability: Packaging machine manufacturers can usually customize according to customer needs. This includes customization of machine size, packaging specifications, control systems, sealing methods, etc. to meet the packaging requirements of customers' specific products.

The Poria transparent pouch packaging machine is a professional packaging equipment that can improve the packaging efficiency and quality of Poria or other small granular items and meet the packaging needs of different specifications. If you are interested in this type of equipment, it is recommended to consult a professional packaging machinery manufacturer or supplier for more detailed information and technical support.

Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm | 300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

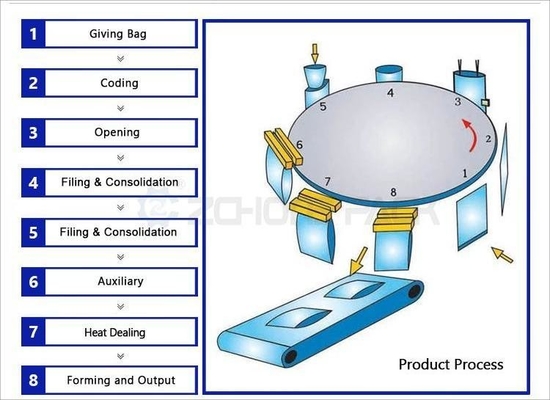

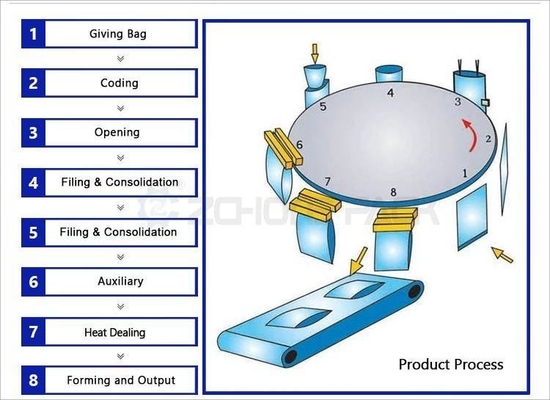

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

| Applicable scope | Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer, etc | ||

(We can provide you with exclusive customized services according to your needs!)

![]()