-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

Automatic Bagged Toy Packaging Machine Since The Elaboration Of The Toy Counting Bowl Lifter

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Automatic Packaging Machine | Product Name | Food Granule Multi-station Packaging Machine |

|---|---|---|---|

| Dimension(L*W*H) | L1900*W1400*H1450 | Weight (KG) | 1300 |

| Voltage | 110V 220V 380V 50hz/60hz | Production Capacity | 20bag/min, 50bag/min, 30bag/min |

| Highlight | Automatic Bagged Toy Packaging Machine,Bagged Toy Packaging Machine,Toy Packaging Machine |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Automatic Bagged Toy Packaging Machine since the Elaboration of the Toy Counting Bowl Lifter

There are many ways to apply toy packaging machines in bagging, one of the most common is to use pre-made bags to package toys. Here is some information about toy bagging machines:

Automated bagging process: Toy packaging machines are able to automatically place toys into pre-prepared packaging bags. This is usually achieved through an automatic feeding system, which provides plastic bags to the packaging machine as needed.

Sealing and packaging: Toy packaging machines will use heat sealing or other sealing methods to close the pre-made bags. This ensures that the toys will not fall or be damaged during the packaging process.

Adaptability: Toy packaging machines can usually adapt to toys of different sizes and shapes, and meet various bagging needs by adjusting machine parameters and settings.

Detection and control system: Toy packaging machines may be equipped with sensors and control systems to detect and control various links in the bagging process. This can ensure sealing quality and packaging consistency.

It should be noted that specific toy bagging machines may have different functions and features, depending on the manufacturer and specific packaging requirements. Therefore, if you have specific toy bagging needs, you can contact us for more accurate information and suggestions.

Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm | 300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

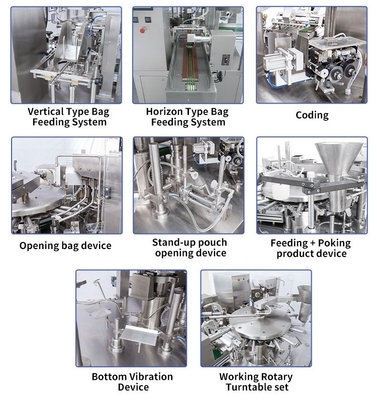

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

| Applicable scope | Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer, etc | ||

(We can provide you with exclusive customized services according to your needs!)

![]()