All Products

-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

Nut Prefabricated Bag Packaging Machine - Efficient and Intelligent Packaging, Helping to Upgrade Quality

Product Details

| Type | Automatic Packaging Machine | Product Name | Food Granule Multi-station Packaging Machine |

|---|---|---|---|

| Dimension(L*W*H) | L1900*W1400*H1450 | Weight (KG) | 1300 |

| Voltage | 110V 220V 380V 50hz/60hz | Production Capacity | 20bag/min, 50bag/min, 30bag/min |

You can tick the products you need and communicate with us in the message board.

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Product Description

Nut Prefabricated Bag Packaging Machine - Efficient and Intelligent Packaging, Helping to Upgrade Quality

In the fast-paced modern food industry, packaging is not only related to the beauty and freshness of the product, but also directly affects the production efficiency and market competitiveness of the enterprise. The nut prefabricated bag packaging machine provides an automated and standardized packaging solution for nut food companies with its high efficiency, intelligence and precision.

Product Introduction

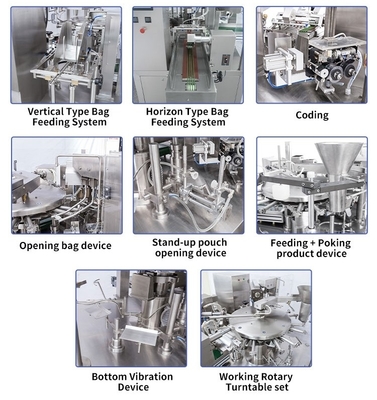

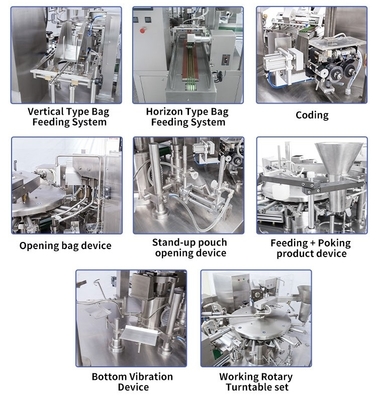

The nut prefabricated bag packaging machine is an automatic packaging equipment specially used for granular foods such as nuts, roasted nuts, dried fruits, etc. It is suitable for a variety of prefabricated bags such as self-supporting bags, zipper bags, four-side sealed bags, flat bags, etc. It can automatically complete a series of packaging processes such as bag opening, metering, filling, sealing, and coding, greatly improving production efficiency and reducing labor costs.

Core advantages

1. Efficient automation to improve productivity

Fully automatic operation, from bag taking, bag opening, metering, filling to sealing, it is completed in one go, greatly reducing manual intervention and improving production efficiency.

High-speed operation can achieve a packaging speed of 30-60 bags per minute to meet different production requirements.

2. Accurate measurement to ensure product quality

With multi-head combination scale, screw scale or measuring cup measurement, the weight of each bag of nuts can be accurately controlled to reduce material waste.

High-precision sensors ensure consistent packaging quality of each bag of nuts and enhance consumer trust.

3. Compatible with a variety of packaging bag types to meet market demand

Supports a variety of bag types such as zipper bags, stand-up bags, flat bags, special-shaped bags, etc., to adapt to the market positioning and packaging styles of different brands.

Suitable for packaging bags of various materials, such as aluminum foil bags, plastic composite bags, environmentally friendly paper bags, etc., to meet the needs of different products.

4. Intelligent control and convenient operation

Adopting PLC intelligent control system, with touch screen operation interface, simple and intuitive, easy to learn and use.

With automatic detection function, such as no bag no filling, no bag no sealing, automatic alarm if the bag is not opened, effectively reducing the loss of packaging materials.

5. Highly safe and in compliance with food hygiene standards

The equipment is made of food-grade stainless steel and meets GMP standards to ensure food safety.

It has dust-proof, anti-static and anti-pollution designs to ensure the freshness and hygiene standards of nuts.

Scope of application

This nut pre-made bag packaging machine is not only suitable for various nut products such as walnut kernels, pistachios, cashews, almonds, peanuts, macadamia nuts, etc., but can also be used for packaging other foods such as melon seeds, dried fruits, candies, tea, instant powders, etc. It is the best choice for food processing companies, chain brands, and OEM factories.

Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm | 300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

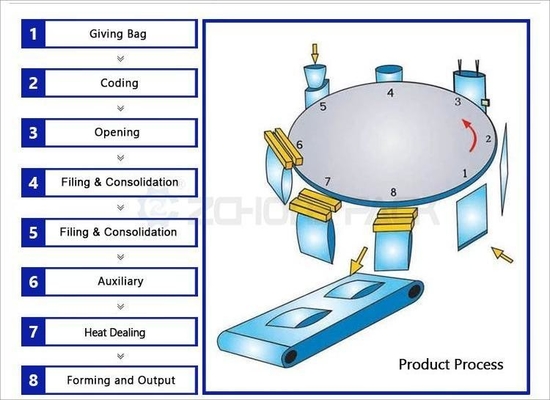

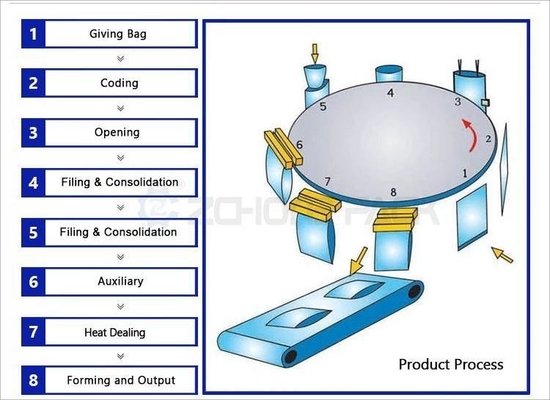

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

| Applicable scope | Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer, etc | ||

(We can provide you with exclusive customized services according to your needs!)

![]()

Recommended Products