-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

Electric Multi-Station Rotary Powder Packaging Machine Foil Pouch for Chili Powder Seasoning for Beverage Food Premade Bags

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-X8300 |

| Minimum Order Quantity | 1set |

| Price | $18,000~$29,900 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1set/15day |

| Type | Multifunctional Packaging Machine | Product Name | Coffee Powder Packaging Machine |

|---|---|---|---|

| Application | Food,Medical,Chemical,Commodity,Machinery & Hardware | Weighing Range | 10g-3kg |

| Certification | CE/ISO9001 | Warranty | 1 Year |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Electric Multi-Station Rotary Powder Packaging Machine Foil Pouch for Chili Powder Seasoning for Beverage Food Premade Bags

Powder packaging machine is a kind of equipment specially used to automatically pack powdered materials (such as milk powder, coffee powder, seasoning, medicine, chemical powder, etc.) into packaging bags or containers according to predetermined weight or volume. It is widely used in food, medicine, chemical, agriculture and other industries, with the characteristics of high efficiency, precision and hygiene.

1. Main types

Classification by degree of automation

Fully automatic powder packaging machine: automatically completes metering, filling, bag making, sealing, coding and other processes, suitable for large-scale production.

Semi-automatic powder packaging machine: requires manual assistance in bagging or starting, suitable for small and medium-sized production.

Classification by packaging form

Vertical packaging machine: suitable for small bag packaging (such as 5g-5kg), can make back seal, three-side seal and other bag types.

Horizontal packaging machine: suitable for large-capacity packaging or canning/bottle packaging.

Pre-made bag packaging machine: directly use pre-made packaging bags, more exquisite appearance.

Classification by metering method

Screw metering type: the volume of powder is controlled by screw rotation, suitable for fine powder with good fluidity (such as milk powder, flour).

Weighing type (electronic scale): high-precision dynamic weighing, suitable for expensive or easy-to-clump powders (such as medicines, additives).

Volumetric cup type: metering through a fixed volumetric cup, suitable for powders with stable density.

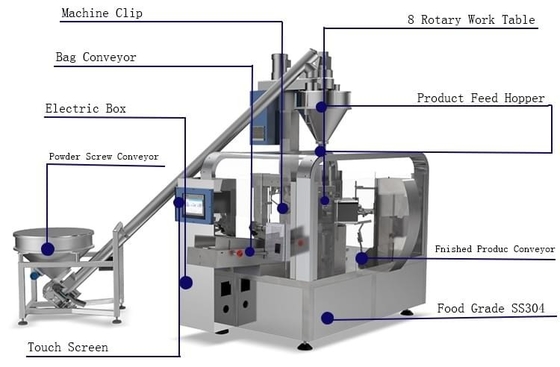

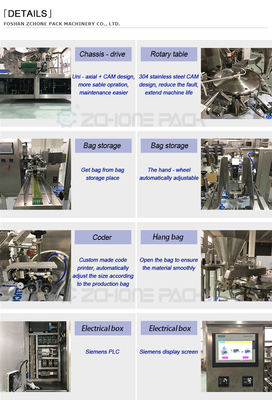

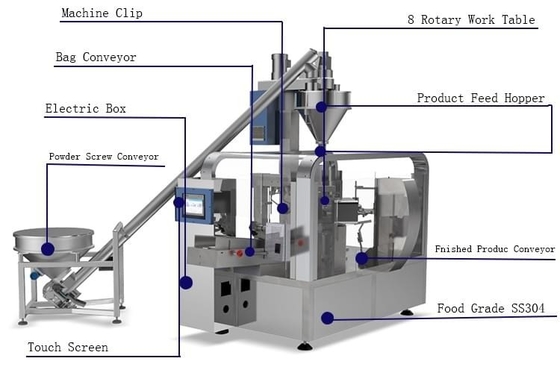

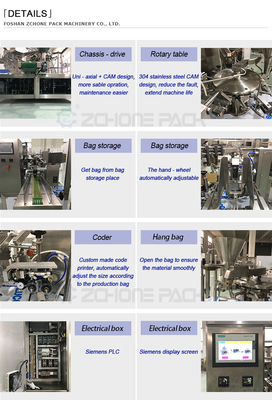

2. Core components

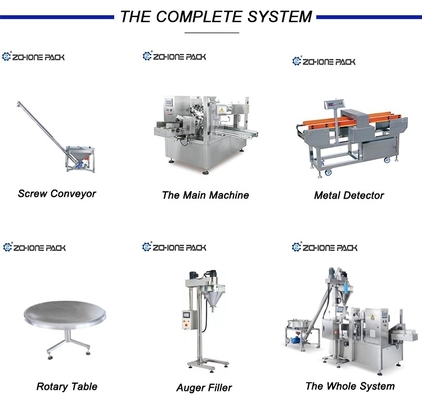

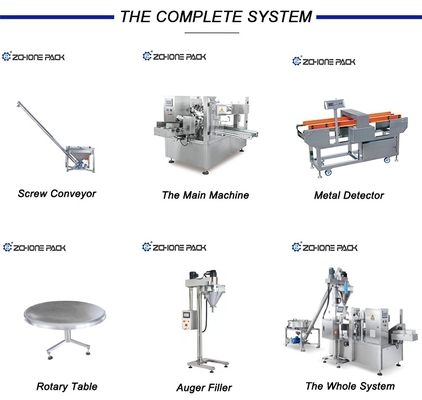

Feeding system: hopper, vibrator or screw conveyor to ensure uniform flow of powder.

Measuring system: screw, weighing sensor or volumetric cup to control packaging weight accuracy.

Bag making/filling system: former (vertical machine) or filling head (horizontal machine) to complete powder filling.

Sealing system: heat sealing device (such as heat sealing strip, ultrasonic sealing) to ensure sealing.

Control system: PLC or microcomputer control, parameters (such as weight, speed, temperature) can be set.

Auxiliary devices: dust collector (anti-dust), coding machine, weight detector, etc.

3. Common problems and solutions

Powder dust: add dust suction device or sealed design.

Inaccurate measurement: adjust the screw speed or calibrate the weighing sensor, check the powder fluidity.

Loose sealing: adjust the heat sealing temperature, pressure or replace the sealing material.

Blockage: add a stirring device or vibrator to the hopper.

4. Application scenario examples

Food industry: packaging milk powder, protein powder, seasoning, instant beverages, etc.

Pharmaceutical industry: packing powdered medicine, Chinese medicine powder, health care products.

Chemical industry: powdered chemicals such as dyes, coatings, and laundry detergents.

Eight-station packing machine Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm | 300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

(We can provide you with exclusive customized services according to your needs!)

![]()

![]()

![]()

![]()