-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

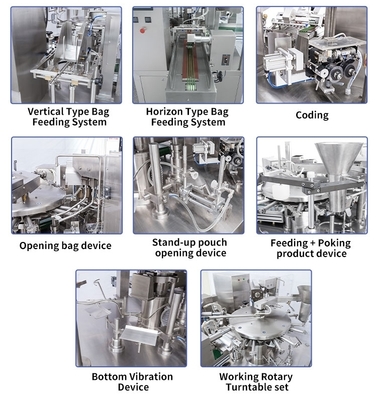

Packing Machine Accessories

-

Filling and capping machine

Cat Litter Packing Machine Solid Granule Multifunctional Bag Packing Machine Nuts Dried Fruit Peanut Granule

| Type | Automatic Packaging Machine | Product Name | Food Granule Multi-station Packaging Machine |

|---|---|---|---|

| Dimension(L*W*H) | L1900*W1400*H1450 | Weight (KG) | 1300 |

| Voltage | 110V 220V 380V 50hz/60hz | Production Capacity | 20bag/min, 50bag/min, 30bag/min |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Cat Litter Packing Machine Solid Granule Multifunctional Bag Packing Machine Nuts Dried Fruit Peanut Granule

The eight-station cat litter bag packaging machine is a device specially used for automatic packaging of cat litter products, which is characterized by high efficiency and precision.

Main features

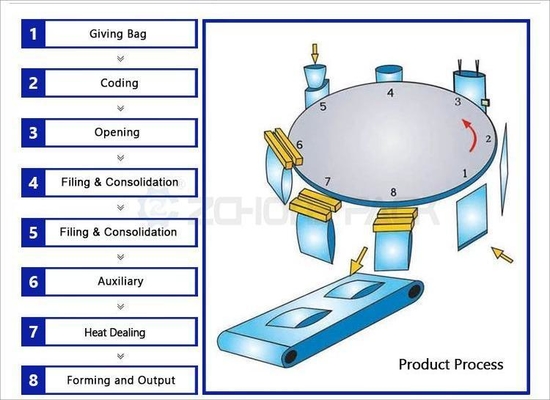

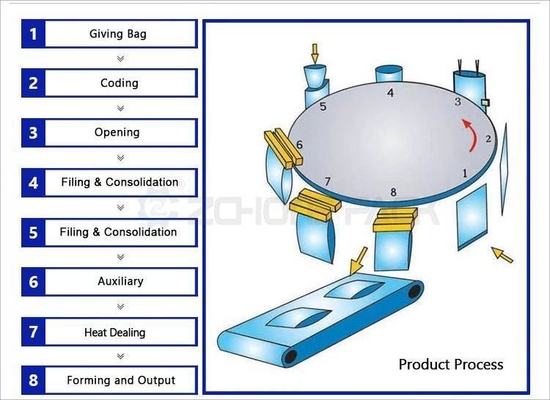

Eight-station design: multiple packaging processes can be carried out simultaneously to improve production efficiency

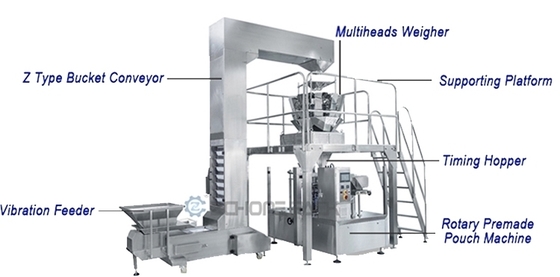

High degree of automation: fully automatic from bag feeding, metering, filling to sealing

Precise metering: high-precision weighing system is used to ensure the consistent weight of each bag of cat litter

Strong adaptability: can handle various types of cat litter (bentonite, tofu litter, crystal litter, etc.)

Multiple bag types: can adapt to packaging bags of different sizes and materials

Technical parameters

Packing speed: usually up to 20-40 bags/minute (depending on the bag type and cat litter type)

Measuring range: generally 5-25kg (adjustable according to demand)

Power supply requirements: 380V/50Hz (or customized according to customer needs)

Air source requirements: 0.6-0.8MPa

Total machine power: about 5-10kW

Application advantages

Improve efficiency: compared with manual packaging, efficiency can be increased by 5-10 times

Reduce waste: accurate metering reduces material loss

Sanitary safety: reduce manual contact and ensure product hygiene

Consistent packaging: ensure that the appearance of each package of products is neat and uniform

Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm | 300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

| Applicable scope | Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer, etc | ||

(We can provide you with exclusive customized services according to your needs!)

![]()

![]()

![]()

![]()