-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

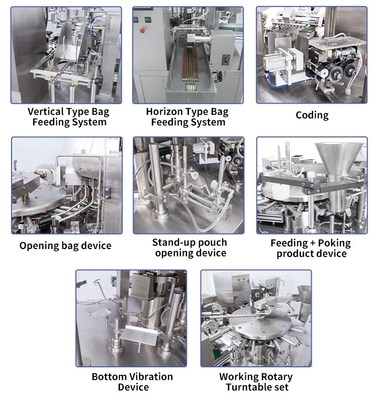

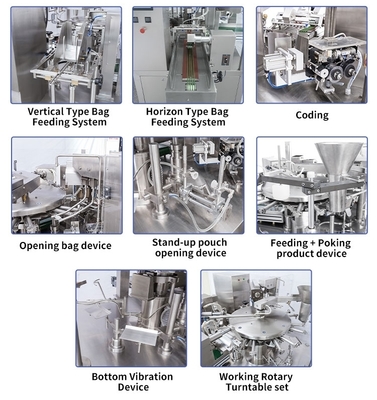

Packing Machine Accessories

-

Filling and capping machine

Automatic Granule Packaging Machine for Food with Multi-Station Dispensing

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Automatic Packaging Machine | Product Name | Food Granule Multi-station Packaging Machine |

|---|---|---|---|

| Dimension(L*W*H) | L1900*W1400*H1450 | Weight (KG) | 1300 |

| Voltage | 110V 220V 380V 50hz/60hz | Production Capacity | 20bag/min, 50bag/min, 30bag/min |

| Highlight | automatic granule packaging machine for food,multi-station dispensing granule packer,food granule packing machine with warranty |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Iodine-containing Cotton Swab Packaging Machine Fully Automatic Counting, Dispensing, and Sealing.

Automatic counting, dispensing, and sealing processes for this cotton swab packaging machine:

1. System Components

Automatic counting and dispensing mechanism

Vibrating plate/conveyor belt: Arranges and aligns the cotton swabs.

Photoelectric sensor/vision system: Counts the swabs (triggering the next action when a set number is reached).

Dispensing gate: Controls the entry of a fixed number of swabs into the packaging area.

Iodine-containing injection system

Micropump + nozzle: Precisely controls the iodine content (e.g., 0.1ml/swab).

Anti-contamination design: Prevents iodine from contaminating the transfer path.

Packaging and sealing module

Heat sealing device: High-temperature sealing of the package edge (controllable temperature to prevent burning).

Control system

PLC/HMI: Parameter settings (counting, iodine content, temperature, etc.).

Fault alarm: Detects material shortage, blockage, and sealing abnormalities.

2. Key Technologies and Parameters

Counting accuracy: Photoelectric sensor response speed ≤ 1ms, error ±0.1%.

Iodine Dosing: Peristaltic pump with an accuracy of ±0.01ml and adjustable flow rate.

Seal Strength: Heat sealing temperature 150-200°C (adjusted depending on the material), pressure 0.2-0.5MPa.

Speed Matching: Unloading → Liquid Filling → Sealing are synchronized.

3. Workflow

Loading: Cotton swabs are placed onto the vibrating plate and automatically arranged on the conveyor.

Counting: When a sensor detects a set number (e.g., 10), the gate opens.

Liquid Filling and Packaging: After the cotton swabs are placed into the pre-made bag, the nozzle completes the iodine injection within a specified timeframe.

Packaging: After the iodine is injected into the bag, the heat seal knife closes.

Output: Finished products are placed into a collection bin, and the system continues in a continuous cycle.

4. Optional Upgrade Features

QR Code Marking: Laser prints batch/date information during sealing.

Weighing Verification: Each package of finished products is weighed, and defective products are automatically rejected.

Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70- 200mm | (L)100-350mm (W)130- 250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm |

300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

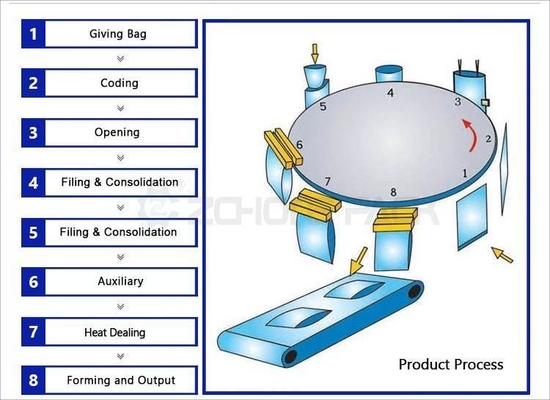

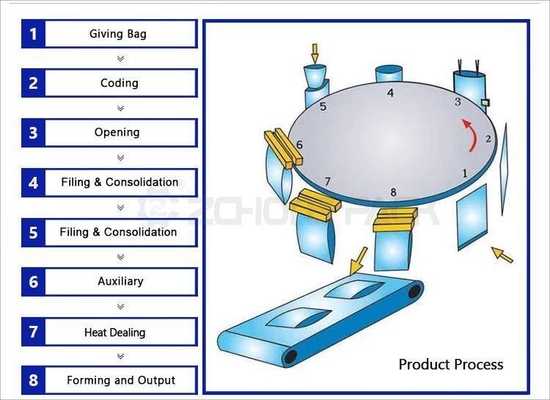

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

| Applicable scope | Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer, etc | ||

(We can provide you with exclusive customized services according to your needs!)

![]()

![]()

![]()

![]()