-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

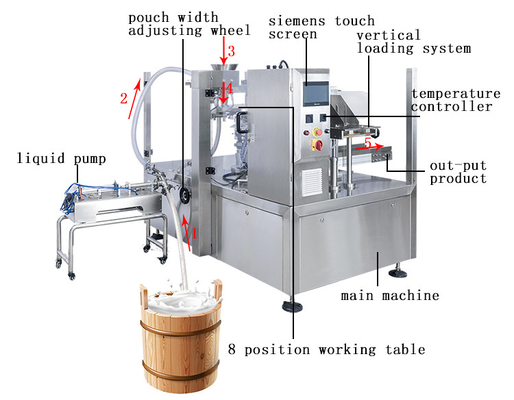

Eight-station Premade Bag Shrimp Slip Packaging Machine

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-8200 |

| Minimum Order Quantity | 1set |

| Price | $18,000~$24,900 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1/sets/15day |

| Product Name | Spout Packing Machine | Place Of Origin | Foshan China |

|---|---|---|---|

| Application | Beverage, Liquid & Juice | Packaging Material | Plastic |

| Voltage | 220V 380V 50/60HZ | Key Selling Points | Automatic |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Eight-station Premade Bag Shrimp Slip Packaging Machine

Eight-station prefabricated bag shrimp slip packaging machine is a kind of equipment specially used for the automatic packaging of shrimp slip products, which is suitable for the automatic filling and packaging of prefabricated bags (self-supporting bags, three-side sealed bags, etc.).

Main features

Eight-station rotary design: adopts a rotary workbench, and eight stations work synchronously to improve packaging efficiency

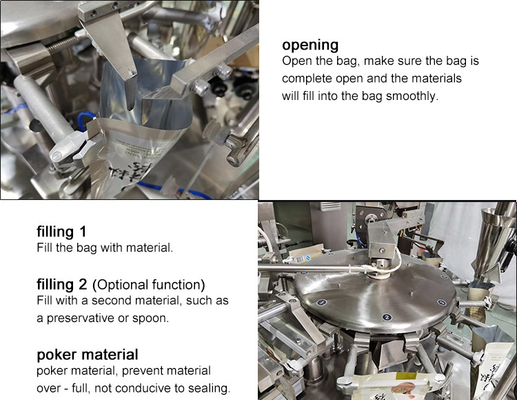

High degree of automation: realize automatic bagging, bag opening, filling, vacuuming (optional), sealing, output and other full-process automation

High-precision measurement: adopts servo control system to ensure the accurate filling weight of shrimp slip

Hygienic design: the food contact part is made of 304 stainless steel, which meets food hygiene standards

Versatility: can adapt to prefabricated bag packaging of different sizes

Technical parameters

Packing speed: 30-50 bags/minute (depending on the bag type and product characteristics)

Packing capacity: 50-500g/bag (adjustable)

Applicable bag types: prefabricated self-supporting bags, three-side sealed bags, four-side sealed bags, etc.

Power requirements: 380V/50Hz (or customized according to customer needs)

Air source requirements: 0.6-0.8MPa

Equipment size: about L×W×H=2000×1500×1800mm

Application areas

Packaging of shrimp slip products

Packaging of other similar viscous foods (such as fish slips, minced meat, etc.)

This packaging machine can significantly improve the packaging efficiency and quality consistency of shrimp slip products, and is an ideal choice for large-scale production of shrimp slip products.

Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm | 300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

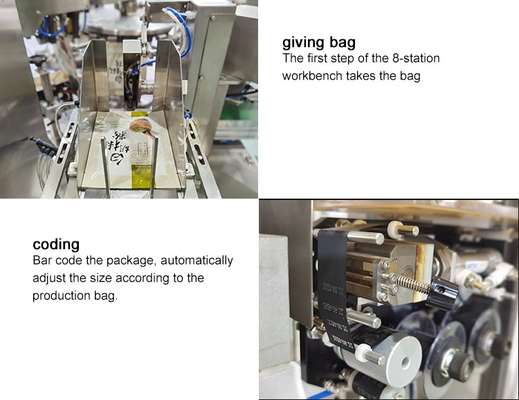

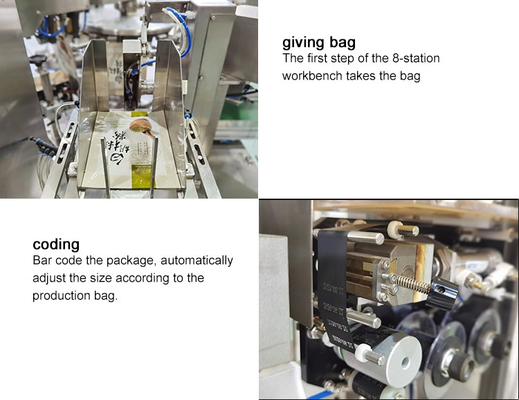

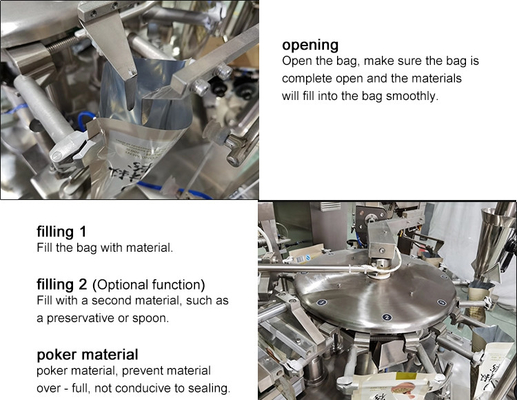

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

(We can provide you with exclusive packaging machine customization services according to your needs! Of course,If you need, we can also provide you with customized bag service)

![]()

![]()

![]()