-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

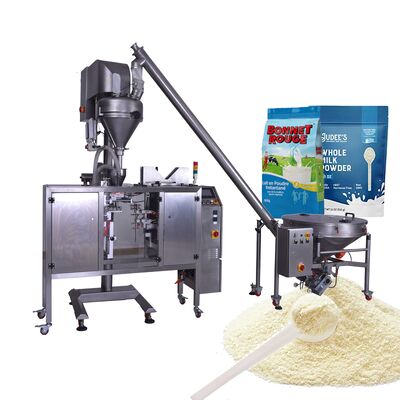

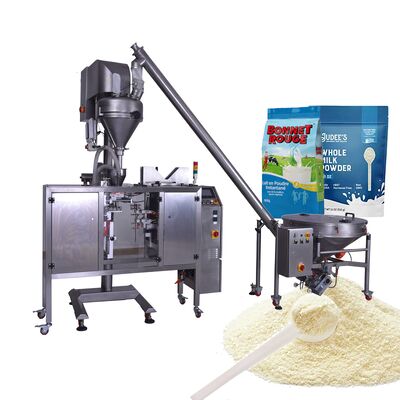

Automatic Weighing and Spoon Placement for Each Bag of Milk Powder Packaging Machine with Screw Meter

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-200 |

| Minimum Order Quantity | 1set |

| Price | $13,900~$19,900 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1/sets/15day |

| Type | Multifunctional Packaging Machine | Product Name | Mini Doypack Packing Machine |

|---|---|---|---|

| Weight (KG) | 1300 | Application | Food, Beverage, Commodity |

| Packaging Material | Plastic | Automatic Grade | Automatic |

| Highlight | automatic milk powder packaging machine,doypack packaging machine with screw meter,weighing and spoon placement packaging machine |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Automatic Weighing and Spoon Placement for Each Bag of Milk Powder Packaging Machine with Screw Meter

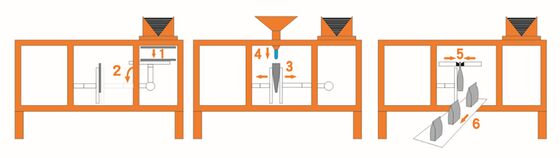

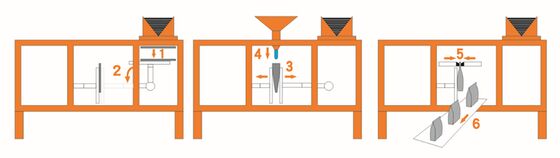

I. Core Workflow (Single-Station Sequential)

A typical single-station machine (as opposed to a multi-station turret machine) operates sequentially:

1. Bag Retrieval/Making: The robotic arm retrieves pre-made empty bags from the bag magazine.

2. Spoon Addition (Key Step):

Spoon Feeding: Spoons are neatly arranged via a vibrating plate or customized hopper and conveyed one by one to the placement position.

Spoon Grabbing and Placement: A mechanical gripper or suction cup grasps a spoon and places it into the bag above the open opening. To ensure proper placement, visual inspection or photoelectric sensing is sometimes used to confirm the spoon is in the bag.

3. Milk Powder Filling:

A precise metering device (such as a screw meter, measuring cup meter, or combination scale) fills a measured amount of milk powder into the bag containing the spoon through the filling head.

Important Sequence: Usually, "spoon first, powder later". Because the scoop is light, if it's placed later, it might be blown away by the milk powder airflow or stand upright on the powder surface, causing sealing problems.

4. Exhausting and Sealing:

Clean the powder from the bag opening (usually using an air blowing device).

Perform the first heat seal (sealing the bag opening).

If necessary, vacuum or purge with nitrogen before the final seal to extend shelf life.

5. Bag Unloading: The sealed bag is released onto a conveyor belt or collection basket.

II. Technical Solutions and Core Challenges

1. Scoop Addition Technology:

Vibratory Feeder Sorting: The most common method, using customized tracks for scoops of specific shapes to ensure consistent scoop orientation.

Visual Guidance Robot: For complex shapes or situations requiring extremely high success rates, a camera is used to recognize the scoop's posture and guide the robot to grasp it. This is more expensive per workstation.

Challenges: Scoops may jam, become entangled (especially plastic scoops), or be improperly placed. The direction of the scoop handle sometimes needs to be controlled to avoid puncturing the packaging bag.

2. Dust Control:

Milk powder is an extremely fine powder, which easily generates dust during filling. Dust can contaminate the sealing area, leading to incomplete seals, and can also contaminate the equipment.

Solution: The equipment needs a good sealing design, localized dust removal points, and clean compressed air purging.

3. Packaging Speed:

"Single-station" means all steps are completed within a single cycle, with speed limited by the slowest step (usually scooping and precise filling).

Typical single-station bagging machines typically have a scooping speed of around 30-60 bags/minute. For higher speeds (e.g., 80 bags/minute or more), multi-station rotary machines should be considered.

4. Measurement Accuracy:

Milk powder is of high value and requires strict weight accuracy (e.g., within ±1 gram). A high-precision servo-driven screw weighing scale with automatic compensation and rejection functions is required.

Machine Specification:

| Item | 200 | 300 | 430 |

| Bag Material | Multilayer Composite Premade Bag (e.g.: PET/PE) | ||

| Bag size | 100mm≤L≤200mm | 100mm≤L≤300mm | 100mm≤L≤430mm |

| 70mm≤W≤150mm | 80mm≤W≤300mm | 80mm≤W≤300mm | |

| Bag Type | 3 Side Seal Bag, Stand-up Bag | ||

| Upgradable Bag Type | N/A |

Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device) |

|

| Speed | 0~26bags/min | 0~15bags/min | |

| Sealing Type | Plain weave | Straight grain, pitch is 1mm (Optional reticulate) | |

| Sealing Width | 8mm | 10mm(5--20mm can be customized) | |

| Voltage | 220V, Single-phase, 50/60HZ, 1KW | 220V, Single-phase, 50/60HZ, 1.2KW | |

| Air Pressure | 0.65Mpa | ||

| Air Consumption | 0.2m³/min | 0.3m³/min | |

| Standard machine, no additional function | |||

| Body Dimension | 1080*535*1010mm | 1770*600*1230mm | 1770*600*1360mm |

| Packing Dimension | 1240*670*1320mm | 1860*710*1550mm | 1860*710*1650mm |

| Export non-fumigation wooden case | |||

(We can provide you with exclusive packaging machine customization services according to your needs! Of course,If you need, we can also provide you with customized bag service)

![]()

![]()