-

Pouches Packing Machine

-

Granule Packing Machine

-

Liquid Packing Machine

-

Powder Packing Machine

-

Mini Doypack Packaging Machine

-

Tea Bag Packing Machine

-

Coffee Packing Machine

-

Vertical Packing Machine

-

Flow Packing Machine

-

Stand Up Pouch Packaging Machine

-

Rotary Vacuum Packaging Machine

-

Filling Machine

-

Horizontal Doypack Packing Machine

-

Premade Bag

-

Packing Machine Accessories

-

Filling and capping machine

Automatic Zipper Stand-Up Pouch Packaging Machine with Bearing for Food Granules/Solids Plastic Film Packaging

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | ZCHONE PACK |

| Certification | ISO,CE |

| Model Number | ZC-430 |

| Minimum Order Quantity | 1set |

| Price | $22,990.00 |

| Packaging Details | Standard export wooden case packaging |

| Delivery Time | 15 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 1/sets/15day |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Type: Multi-Function Packaging Machine | Weight (KG) | 880 |

|---|---|---|---|

| Applicable Industries | Hotels, Garment Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops | Application | Food, Commodity, Medical, Chemical, Machinery & Hardware |

| Core Components | Motor, Pressure Vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox | Packaging Type | Stand-up Pouch, Bags, Pouch |

| Voltage | 220V,50/60HZ,1KW | Production Capacity | 30bag/min |

| Highlight | automatic zipper pouch packaging machine,stand-up pouch machine for food granules,mini doypack machine with bearing |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Automatic Zipper Stand-Up Pouch Packaging Machine with Bearing for Food Granules/Solids Plastic Film Packaging

I. Equipment Definition

This is an automated packaging machine specifically designed for single-station completion of chocolate bean metering, filling, and sealing. It is typically suitable for small-batch, multi-variety, and refined production needs, or as an independent unit in a production line.

II. Core Features

1.This is an automated machine that uses pre-made bags, employing a robotic arm to pick up, open, meter, fill, and seal the bags at a single station, ultimately completing the packaging.

2.Its "single-station" design means that all actions (bag picking, opening, filling, sealing, and output) are completed cyclically on the same main workstation, resulting in a compact structure and clear workflow.

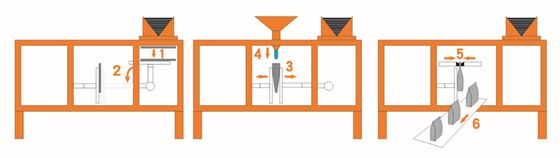

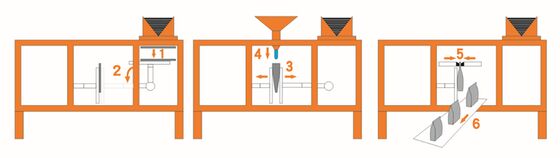

III. Detailed Workflow

1. Bag Picking and Loading: The robotic arm or suction cup accurately picks up a bag from the pre-made bag hopper and transfers it to the bag opening station of the main workstation.

2. Bag Opening: A high-precision bag opening device (such as grippers, suction cups, or struts) stably and completely opens and holds the bag opening, awaiting filling. This is crucial for successful filling.

3. Metering and Filling: Metered chocolate beans (usually using a multi-head scale or precision measuring cup) are fed into the opened bag through a funnel or flexible discharge tube. This process can be equipped with anti-splash and anti-static devices to ensure proper placement of the beans.

4. Auxiliary Functions (Optional): Before sealing, functions such as adding desiccant cards and nitrogen filling for preservation can be integrated.

5. Sealing: After the bag opening is prepared, it is heat-sealed (for laminated bags) or cold-sealed (for some paper bags). Various sealing methods are available, such as straight seals, arc seals, and perforated seals.

6. Output: The packaged bags are released onto a conveyor belt, which can be connected to equipment for weight verification, metal detection, and coding, finally entering a collection bin or proceeding to the next packaging stage (such as boxing).

IV. Core Advantages (Why Choose This Packaging for Chocolate Beans?)

1. Superior Packaging Appearance: Pre-printed bags feature exquisite designs, vibrant colors, and a neat, aesthetically pleasing seal, making them ideal for high-end and gift markets.

2. Wide Bag Type Adaptability: Capable of handling almost all types of pre-printed bags, including stand-up pouches, zipper bags, four-side seal bags, tote bags, and irregularly shaped bags, offering an extremely diverse range of packaging options.

3. Extremely High Yield: Since the bags are pre-made, there is no risk of defective bag production. Mature functions such as bag opening inspection and empty bag rejection ensure consistent quality of the finished bags.

4. Product-Friendly: The material flow path is typically shorter and smoother, and customizable flexible flow channels reduce breakage and friction of chocolate beans, making it especially suitable for candied or fragile beans.

5. Good Material Compatibility: Adaptable to various composite materials, including paper, aluminum foil, PET/PE, etc., facilitating the creation of high-barrier, freshness-preserving packaging.

6. Easy to change production: When changing to bags of different sizes, the main changes are to the bag clamping handles and a few molds, which is relatively quick.

Machine Specification of Rice Packing Machine:

| Item | 200 | 300 | 430 |

| Bag Material | Multilayer Composite Premade Bag (e.g.: PET/PE) | ||

| Bag size | 100mm≤L≤200mm | 100mm≤L≤300mm | 100mm≤L≤430mm |

| 70mm≤W≤150mm | 80mm≤W≤300mm | 80mm≤W≤300mm | |

| Bag Type | 3 Side Seal Bag, Stand-up Bag | ||

| Upgradable Bag Type | N/A |

Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device) |

|

| Speed | 0~26bags/min | 0~15bags/min | |

| Sealing Type | Plain weave | Straight grain, pitch is 1mm (Optional reticulate) | |

| Sealing Width | 8mm | 10mm(5--20mm can be customized) | |

| Voltage | 220V, Single-phase, 50/60HZ, 1KW | 220V, Single-phase, 50/60HZ, 1.2KW | |

| Air Pressure | 0.65Mpa | ||

| Air Consumption | 0.2m³/min | 0.3m³/min | |

| Standard machine, no additional function | |||

| Body Dimension | 1080*535*1010mm | 1770*600*1230mm | 1770*600*1360mm |

| Packing Dimension | 1240*670*1320mm | 1860*710*1550mm | 1860*710*1650mm |

| Export non-fumigation wooden case | |||

(We can provide you with exclusive packaging machine customization services according to your needs! Of course,If you need, we can also provide you with customized bag service)

![]()

![]()